Biodegradable Blown Film Extrusion

Biodegradable Plastic film blowing machine suit to produce biodegradable plastic film,PLA film,PBAT film,PVA film.

Inquiry Basket

Product Details

Biodegradable Blown Film Extrusion

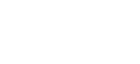

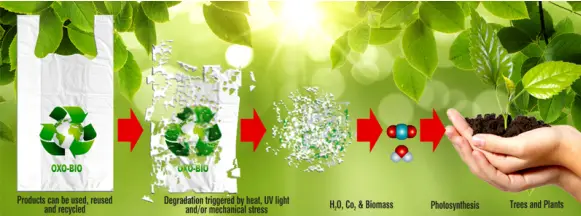

The method referred to as Biodegradable Blown Film Extrusion employs materials such as PLA, PBAT, corn starch, calcium carbonate, and various biodegradable substances to produce vest and trash bags. Key advantages of this process include complete degradability and a beneficial influence on the environment. The die-head is equipped with an internal 8-hole inflow feed system, specifically designed to optimize the creation of film from biodegradable materials like PLA and PBAT during the blown film extrusion process.

Degradable plastic bags can decompose into carbon dioxide, water, methane, and other naturally occurring elements, allowing them to assimilate into the carbon cycle over a specified period and under certain conditions.

biodegradable blown film extrusions

biodegradable blown film extrusions

| Model | SJ-50-PLA800 | SJ-55-PLA1000 |

| Material | Biodegradable PLA resin | Biodegradable PLA resin |

| Diameter of screw | Φ50 | Φ55 |

| L/D Ratio | 30:1 | 30:1 |

| Max. Film width(mm) | 800 | 1000 |

| Film thickness (mm) | 0.015-0.10 | 0.015-0.10 |

| Extrusion capacity | 30-80kg/h | 50-100kg/h |

| Main motor | 18.5kw | 22kw |

| Hard Tooth Face Gear Box | 173# | 180# |

| Air ring | Double lip | Double lip |

| Machine Size | 4500*2600*5200mm | 4900*2600*5200mm |

| Weight | 2000kgs | 2500kgs |

biodegradable blown film extrusions

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

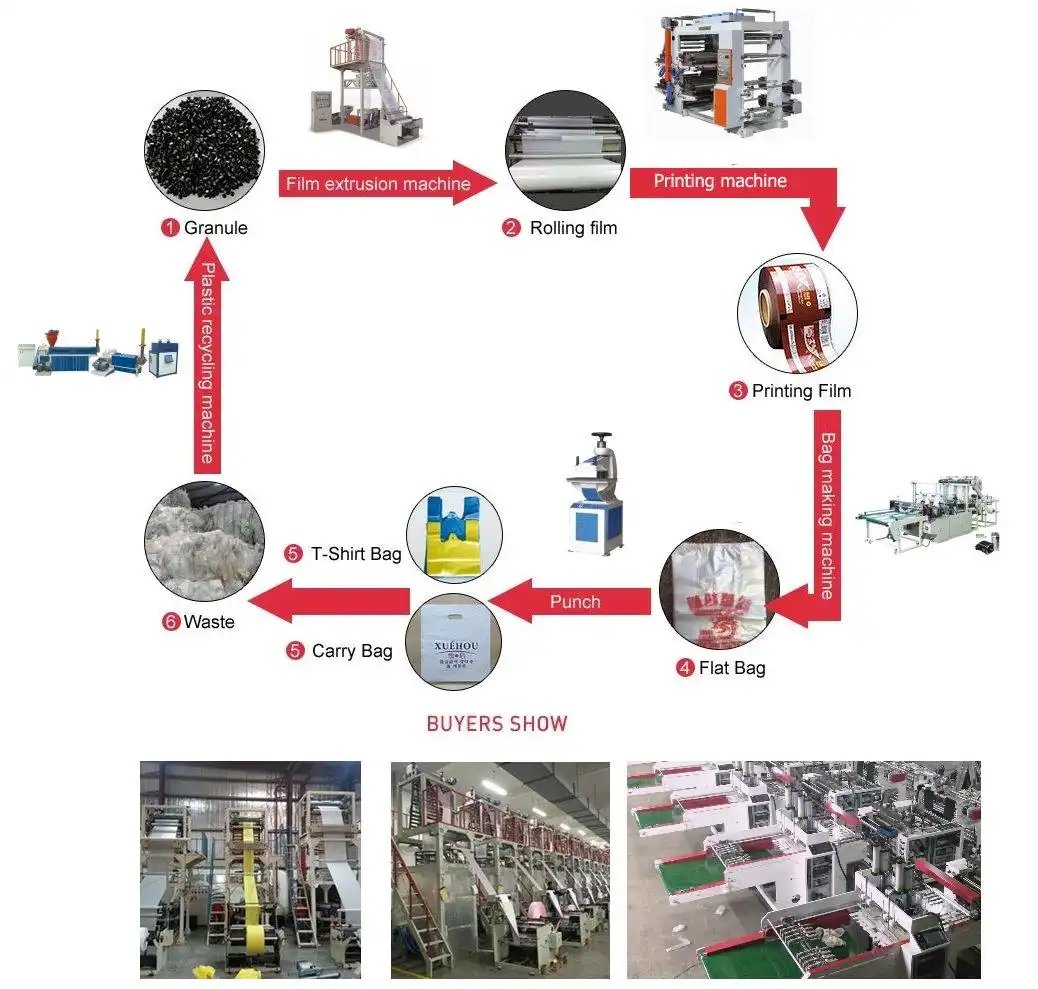

Shipment

shipment of plastic bag machine

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

instalment service

install machines in customer factory

Machine parts supplier

Our Main parts cooperator as following brand,but standard parts all made from China.

Material supplier

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company