High Speed Four Colors Flexo Printing Machine

Inquiry Basket

Product Details

High Speed Four Colors Flexo Printing Machine

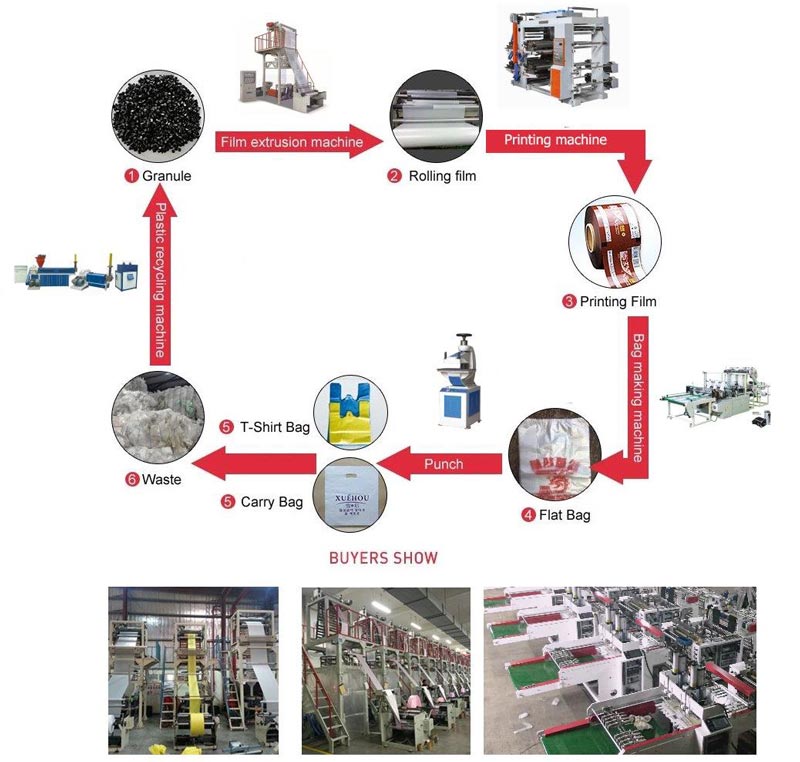

The Four Colors Flexo Printing Machine provides an effective solution for printing a range of packaging materials such as polyethylene, polypropylene bags, cellophane, and roll paper. It is an essential tool for manufacturing paper packaging bags, supermarket totes, vest bags, and garment bags.

This machine is engineered for user-friendliness, offering flexible startup options along with accurate color registration. It includes a meter counter that enables the customization of print quantities and features an automatic shutdown mechanism. The pneumatic printing cylinder is designed to automatically rise and fall for ink mixing, while the Anilox cylinder ensures uniform ink distribution. A reliable drying system allows the machine to pause operations when required. Furthermore, the longitudinal register device allows for ongoing adjustments, and the motor speed is frequency-controlled to support various printing speeds.

printed plastic bag

printed plastic bag

| YT-A4600 | YT-A4800 | YT-A41000 | YT-A41200 | |

| Max.material width | 600mm | 800mm | 1000mm | 1200mm |

| Max.printing width | 560mm | 760mm | 960mm | 1160mm |

| Machine weight | 4000kgs | 4500kgs | 4900kgs | 5200kgs |

| Outline dimension | 5.5×1.8x3m | 5.5×2.0x3m | 5.5×2.2x3m | 5.5×2.4x3m |

| Printing colors | 4 colors (4+0,3+1,2+2) | |||

| Printing length | 300-1000mm | |||

| Machine speed | 150m/min | |||

| Printing speed | 100m/min (120m/min with optional:chamber doctor blade) | |||

| Suitable Material | PAPER∶15~300g/m²、 NONWOVEN∶15-120G、PC∶10-120μm、OPP∶10-100μm、BOPP∶10-100μm、PE∶15-150μm、NY∶10-120μm、 PET∶10-100μm、CPP∶10-100μm | |||

| Adjusting of register | Electric motor control (vertical and horizontal) | |||

| Material of Plate | Resin | |||

| Constitution of Printing | Ceramic Anilox roller 4pcs、single doctor blade 4pcs、printing Cylinder for printing length 400mm、 Camera & PLC touch screen control

| |||

| Optional device :chamber doctor blade; | ||||

| Working Principle | synchronous belt driving | |||

| Printing precision | +/-0.15mm | |||

| Thickness of Plate (including the glue) | 1.7mm (please note us for different thickness) | |||

| Machine Voltage | 380V 50/60HZ 3PH | |||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Flexo Printing Machine Loading container,ship to other country.

Flexo printing machine,film blowing machine in customer fatory

Install Strech Film Machine in Mexico Customer Factory

Our Main parts cooperator as following brand(standard parts all made from China).

Drinking Straw Material Supplier

Global Service Network